How to Prevent Water-Filled Barricades from Cracking When They Freeze

Freezing temperatures can cause water barriers to crack and fail. Learn why it happens and how to reduce freeze-related damage with practical winter handling tips.

Water Barricades are commonly used for temporary traffic control, but freezing temperatures can create serious problems in winter conditions.

When water inside a barricade freezes, it expands, increasing internal pressure that can lead to cracking, deformation, or loss of structural integrity. The goal isn’t always to stop water from freezing entirely, but to prevent damage when freezing occurs.

This guide explains why water-filled barricades crack in cold weather and outlines practical steps to reduce freeze-related damage so they remain functional and safe during winter use.

Why Water-Filled Barricades Crack When They Freeze

Water expands as it freezes. Inside a water-filled barricade, this expansion creates internal pressure against the barrier walls and seams.

When temperatures drop low enough for sustained freezing, the pressure has nowhere to escape, increasing stress on the barricade’s structure.

Over time, this stress can lead to cracking, splitting, or deformation, especially at joints, corners, or molded connection points.

Repeated freeze-and-thaw cycles can worsen the damage, weakening the barricade even if cracks are not immediately visible.

Cold conditions can also make barrier materials less flexible, which reduces their ability to absorb pressure changes.

As a result, water-filled barricades are more likely to fail during winter if freezing conditions are not managed properly.

Risks of Using Frozen or Damaged Water-Filled Barricades

When water-filled barricades are cracked or deformed, their ability to function properly can be reduced. Structural damage may affect how barriers connect, align, or remain stable, increasing the risk of movement or separation in active traffic areas.

Damaged barricades can also lead to operational challenges, including leaks, uneven weight distribution, and difficulty handling or repositioning barriers during winter conditions.

Once temperatures rise, existing damage may worsen, shortening the usable life of the barricade.

Using compromised barricades often results in unplanned replacements, downtime, and added safety concerns, especially on projects that continue through changing winter conditions.

Practical Ways to Reduce Freeze-Related Damage

Freezing conditions can’t always be avoided during winter, but the risk of damage can be reduced with the right preparation and handling. The following practices focus on limiting internal pressure and minimizing stress on the barricade structure.

Drain Water Before Prolonged Freezing Temperatures

Removing water before extended periods of freezing prevents internal pressure from building as water expands. This is especially important when temperatures are expected to remain below freezing overnight or for several days.

Monitor Weather Conditions Closely

Short cold snaps may not pose the same risk as sustained freezing. Tracking temperature patterns helps determine when barriers should be drained or removed from service to avoid repeated freeze-and-thaw cycles.

Refill Barriers Only When Temperatures Stabilize

Refilling barriers too early can trap water that freezes again overnight. Waiting until temperatures remain consistently above freezing reduces the chance of recurring internal pressure.

Follow Manufacturer Guidance for Winter Use

Barrier design, materials, and connection points affect how freezing conditions impact performance. Manufacturer recommendations provide guidance specific to each barricade model and intended application.

Can Additives Like Salt or Antifreeze Prevent Cracking?

Adding substances to the water inside a barricade is often suggested as a way to reduce freezing damage.

While some additives can lower the freezing point of water, they also introduce new risks that can affect barricade integrity and safety.

Using Salt in Water-Filled Barricades

Salt can lower the freezing point of water, but it does not eliminate freezing under sustained cold conditions. Its use also comes with drawbacks that should be considered carefully.

- Salt can still allow partial freezing, which means internal pressure may still build

- Residue may increase material wear or corrosion over time

- Salt concentration is difficult to control in large barricade systems

- Environmental and site restrictions may limit its use

Because of these factors, salt is not a reliable solution for preventing cracking in water-filled barricades during winter.

Why Antifreeze Is Not Recommended

Antifreeze is sometimes assumed to be an effective option, but it is generally not suitable for use in water-filled traffic barricades.

- Most antifreeze products are toxic and environmentally hazardous

- Leaks can create contamination risks on jobsites

- Barrier manufacturers typically do not approve antifreeze use

- Improper mixtures can still freeze or separate

For these reasons, antifreeze is not considered a safe or compliant method for managing freezing conditions in water-filled barricades.

Cold-Weather Maintenance Tips for Water-Filled Barricades

Winter conditions place additional stress on water-filled barricades, even when steps are taken to reduce freezing damage. Regular inspection and handling practices help identify issues early and prevent minor damage from becoming operational problems.

Recommended cold-weather maintenance practices include:

- Inspect barriers regularly during winter use

Check for visible cracks, deformation, or leaks, especially after freeze-and-thaw cycles.

- Monitor connection points and joints

Stress from freezing often shows first at seams and molded connectors.

- Address partial freezing promptly

Barriers that are partially frozen may shift weight unevenly, affecting stability and alignment.

- Avoid moving frozen or rigid barriers when possible

Cold temperatures can make materials less flexible, increasing the risk of damage during handling.

- Remove damaged barriers from service early

Continued use of cracked or leaking barricades can lead to further failure and safety concerns.

Consistent winter maintenance helps extend barricade life and reduces unexpected issues during ongoing projects.

When Water-Filled Barricades May Not Be the Right Choice in Winter

Water-filled barricades work well in many environments, but certain winter conditions make them less practical. In these cases, the risk of freezing-related damage or operational challenges may outweigh their benefits.

Prolonged or Extreme Freezing Temperatures

Projects located in regions with extended periods below freezing make it difficult to manage water levels reliably. When water remains frozen for long durations, the risk of cracking and material stress increases significantly.

Long-Term Winter Installations

For installations that must stay in place throughout the winter, repeated freeze-and-thaw cycles can accelerate wear. Over time, this can shorten barricade lifespan and increase maintenance needs.

Limited Access for Draining or Maintenance

Sites where barriers cannot be easily drained, inspected, or serviced during winter may face higher failure risk if freezing occurs unexpectedly.

Projects Requiring Frequent Repositioning

Frozen or rigid barriers are harder to move safely. In winter operations that require regular layout changes, this can slow work and increase the chance of handling damage.

In these situations, evaluating alternative traffic control options or seasonal adjustments can help reduce winter-related issues.

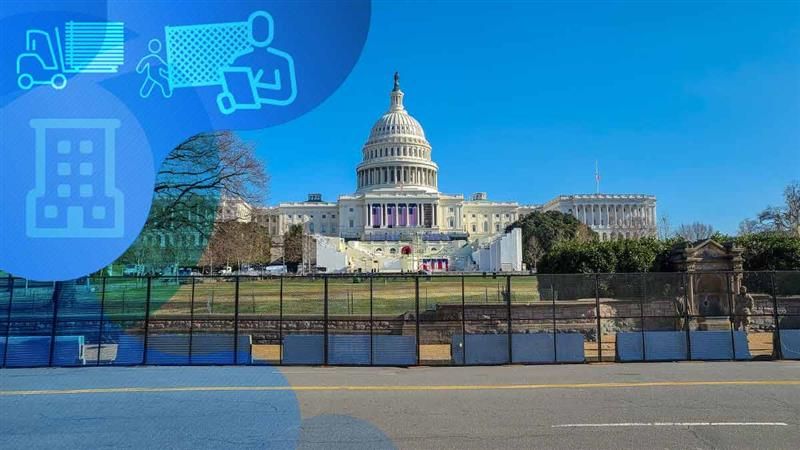

Water-Filled Barricades from SONCO

SONCO supplies water-filled barricades designed for temporary traffic control and active jobsite use.

These barriers are used across construction, roadwork, and facility environments where flexibility and visibility are required.

With 50 years of experience supporting safety and traffic control operations, SONCO provides access to stocked products, consistent availability, and guidance to help teams choose the right barricade type for seasonal conditions.

Support extends beyond the product itself, with assistance on use considerations, compatibility, and deployment across different project needs.

Trend now

Theme Park Safety: Avoiding Fines and Accidents with Crowd Control

Learn how crowd control products help keep theme parks safe, avoid accidents, and improve operations. Explore SONCO’s solutions for better crowd management.

Anti Scale Fence for Temporary High-Security Needs

Anti scale fence designed for temporary high-security perimeters, crowd control, protests, and emergency response where standard fencing falls short.

Why Bike Rack Barricades Are the Go-To Choice for Crowd Control

Explore why bike rack barricades are the go-to for crowd control. Learn how these versatile, durable barriers keep events, construction sites, and more organized.